“See? It doesn’t move.”

Mr. Kim, my group’s guide for the day, gleefully blows at the sheet of paper held to his face. “Hanji is extremely breathable and can regulate humidity, so it was traditionally used for insulating doors and windows. And it lasts for thousands of years, too, making it the perfect archival medium.”

Anyone who calls themselves a writer, I believe, has some degree of obsession with paper. We hoard ever-pristine notebooks, believing them too beautiful for our scrawled thoughts, and sniff the pages of books we read. Needless to say, visiting Andong Hanji was a highlight of my trip around Korea’s Gyeongbuk province.

What is hanji?

Hanji (literally, ‘Korean paper’) dates back to somewhere between the 3rd and 6th century. Made by hand, hanji boasts exceptional qualities that give it a much longer lifespan than modern wood-pulp paper. One of civilization’s oldest surviving woodblock prints, the Great Dharani Sutra, was discovered in nearby Bulguksa and dates back to the 8th century – and was printed on a mulberry paper scroll.

Like some types of Japanese paper (washi), hanji is made from the inner bark of the paper mulberry (Broussonetia papyrifera) plant and the mucilage of the aibika plant (Abelmoschus manihot). This formula gives the paper a near-neutral pH, enabling it to last longer in the environment as compared to modern paper, which is typically acidic. However, handmade hanji is about 20 times more expensive than commercial paper – so it’s used sparingly these days by artists and calligraphers!

Learning how hanji is made

It’s the inner bark of the paper mulberry plant that’s turned into paper; the outer bark is typically skinned, while the plant roots are woven into rope. As we follow Mr. Kim around, I learn why a vegetal smell permeates the factory: the inner bark (baekpi) is boiled to mush, rinsed thrice, and then bleached to prepare it for papermaking. In the meantime, the sticky mucilage from the aikiba plant is used as the “glue” that binds the bark fibres into paper.

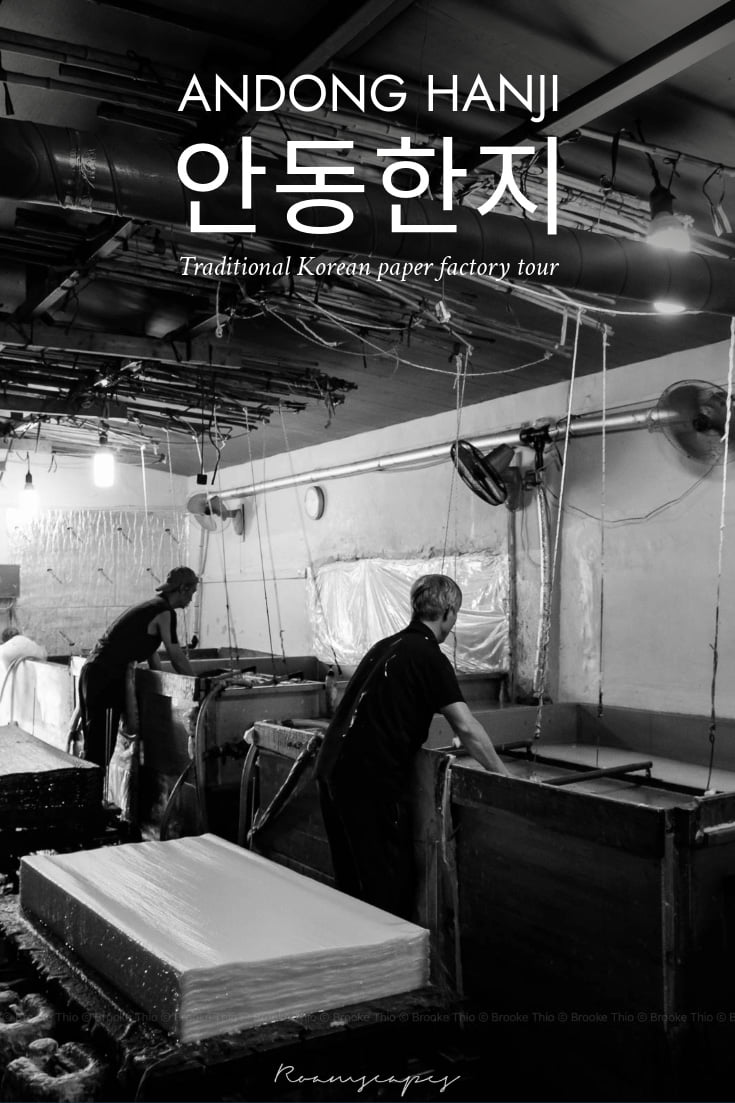

Once the bark fibres, mucilage, and water are mixed together, the magic happens. The hanji craftsman immerses a large framed bamboo screen in sinks filled with the paper soup, and swinges it to and fro – straining the fibres into a thin yet perfectly even layer of pulp. Then, the frame is unlatched and the bamboo screen removed.

In one swift motion, the paper is laid atop a dripping wet stack – and the craftsman turns back to make the next sheet.

Finally, the paper is hand-dried by brushing it onto a heated steel board and leaving it for a few minutes. Like the sheet-makers, the drying crew move like well-oiled machines, breaking character only to laugh at our clumsy attempts at paper-making.

Making my own Korean paper

At Andong Hanji Paper Factory, visitors can try making hanji as well: for KRW 5,000, you’ll get to form a roughly A4-sized sheet of paper.

After trying it out, it became clear why hanji is so highly valued – forming a smooth, even sheet of paper on the screen is tougher than it looks, and the larger the sheet, the harder it gets. It takes a lifetime of experience to be able to make consistently fine paper by hand – as well as significant strength and stamina.

You can’t make a thicker sheet just by straining for longer, either – the excess simply slips away. Instead, thickness is measured by hap, or the number of sheets layered together before drying. Each sheet is separated by a string during the sheet-making process, and 4 hap, Mr. Kim tells us, is considered “presidential quality”.

Admiring Korean paper craft

Although Andong Hanji is a factory, it does have a little gallery-slash-gift shop showcasing hanji artwork and stationery that visitors can buy. It’s fascinating to see how artisans have turned such a simple material into some amazing products, from masks (used in traditional Andong mask dances) to lanterns and trinket boxes. If you’d like to learn more about Korean paper, make sure to visit the Hanji Theme Park in Jeonju or the Hanji Center in Seoul.

After witnessing how hanji is made and trying it myself, I left with a newfound respect for handmade paper – and a piece of it I’ll always deem too precious to use.

Getting to Andong Hanji Paper Factory

Getting to Andong Hanji is tricky: it’s about 1.5 hours away from Andong City via public bus, although Andong is easily accessible via the KTX high-speed rail network. Thus, it’s worth a stop only if you’re planning to travel around Gyeongbuk province.

PLAN YOUR TRIP

Find more Korea travel inspiration with our guides. Better yet, start planning your trip!